Aquifer Storage Recovery (ASR) is the storage of water in a well during times when water is available,  and

recovery of the water from the same well during times when it is

needed. ASR provides a cost-effective solution to many of the world’s

water management needs, storing water during times of flood or when

water quality is good, and recovering it later during times of drought

or when water quality from the source may be poor. Large water volumes

are stored deep underground, reducing or eliminating the need to

construct large and expensive surface reservoirs. In many cases, the

storage zones are aquifers that have experienced long term declines in

water levels due to heavy pumping to meet increasing urban and

agricultural water needs. Groundwater levels can then be restored if

adequate water is recharged.

and

recovery of the water from the same well during times when it is

needed. ASR provides a cost-effective solution to many of the world’s

water management needs, storing water during times of flood or when

water quality is good, and recovering it later during times of drought

or when water quality from the source may be poor. Large water volumes

are stored deep underground, reducing or eliminating the need to

construct large and expensive surface reservoirs. In many cases, the

storage zones are aquifers that have experienced long term declines in

water levels due to heavy pumping to meet increasing urban and

agricultural water needs. Groundwater levels can then be restored if

adequate water is recharged.

and

recovery of the water from the same well during times when it is

needed. ASR provides a cost-effective solution to many of the world’s

water management needs, storing water during times of flood or when

water quality is good, and recovering it later during times of drought

or when water quality from the source may be poor. Large water volumes

are stored deep underground, reducing or eliminating the need to

construct large and expensive surface reservoirs. In many cases, the

storage zones are aquifers that have experienced long term declines in

water levels due to heavy pumping to meet increasing urban and

agricultural water needs. Groundwater levels can then be restored if

adequate water is recharged.

and

recovery of the water from the same well during times when it is

needed. ASR provides a cost-effective solution to many of the world’s

water management needs, storing water during times of flood or when

water quality is good, and recovering it later during times of drought

or when water quality from the source may be poor. Large water volumes

are stored deep underground, reducing or eliminating the need to

construct large and expensive surface reservoirs. In many cases, the

storage zones are aquifers that have experienced long term declines in

water levels due to heavy pumping to meet increasing urban and

agricultural water needs. Groundwater levels can then be restored if

adequate water is recharged.The main driving force behind the current rapid implementation of ASR technology around the world is water supply economics. ASR systems can usually meet water management needs at less than half the capital cost of other water supply alternatives. When compared to alternatives requiring

construction of water treatment plants and surface reservoirs to meet

increasing peak demands, potential savings have been known to exceed

90%. A second important driving force has been the increased recognition

of this technology as being good for the environment, aquatic and

terrestrial ecosystems. By reducing or eliminating the need for

construction of dams, and by providing reliable water supplies through

diversions of flood flows instead of low flows, ASR systems are usually

considered to be environmentally friendly.

construction of water treatment plants and surface reservoirs to meet

increasing peak demands, potential savings have been known to exceed

90%. A second important driving force has been the increased recognition

of this technology as being good for the environment, aquatic and

terrestrial ecosystems. By reducing or eliminating the need for

construction of dams, and by providing reliable water supplies through

diversions of flood flows instead of low flows, ASR systems are usually

considered to be environmentally friendly.

Storage zones range in depth from as shallow as about 75 m (200 ft.) to as deep as 900 m (2700 ft.). Groundwater levels in the storage zones range from as much as 10 m (30 ft.) above land surface to more than 300 m (900 ft.) below land surface. Natural water quality in the storage zone ranges from fresh, suitable for drinking without treatment, to brackish,including total dissolved solids concentrations up to about 5000 mg/l. Most sites have one or more natural water quality constituents that are unsuitable for direct potable use except following treatment. Such constituents may include iron, manganese, fluoride, hydrogen sulfide, sulfate, chloride, radium (224/226 /228), gross alpha radioactivity, and other elements which are typically displaced by the stored water as the bubble is formed underground. At one site, not currently in operation, ASR was shown to be feasible and highly cost-effective storing drinking water in an aquifer containing seawater. For most of these sites, it is first necessary to properly develop the storage zone around the well, after which it is possible to recover the same volume as that stored. At a few, more challenging sites water quality, hydraulic or geochemical constraints may limit recovery to somewhat less than the volume stored.

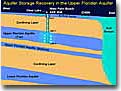

Water is stored deep underground in water-bearing geologic formations,

or "aquifers" that may be in sand, clayey sand, sandstone, gravel,

limestone, dolomite, glacial drift, basalt and other types of geologic

settings. Stored water displaces the water naturally present in the

aquifer, creating a very large bubble around the well. The bubble is

usually confined by overlying and underlying geologic formations that do

not produce water, however at several sites the aquifer is unconfined.

Storage volumes in these bubbles range from as small as about 50 Ml (13

million gallons) in individual ASR wells, to as much as 10,000 Ml (2.5

BG) or more in large ASR wellfields.

ASR Applications

Most ASR systems provide seasonal water storage,

storing water during the wet season and recovering it during the

following dry season. Many also use ASR for water banking, storing water

during wet years and recovering it years laterduring extended droughts.

Increasingly many water managers are constructing ASR systems to ensure

reliability during emergencies, whether severe floods, earthquakes,

contamination incidents, pipeline breaks, or potential damage due to

warfare or sabotage. Actually there are at least 22 ASR applications,

and others will undoubtedly follow.

Most ASR systems provide seasonal water storage,

storing water during the wet season and recovering it during the

following dry season. Many also use ASR for water banking, storing water

during wet years and recovering it years laterduring extended droughts.

Increasingly many water managers are constructing ASR systems to ensure

reliability during emergencies, whether severe floods, earthquakes,

contamination incidents, pipeline breaks, or potential damage due to

warfare or sabotage. Actually there are at least 22 ASR applications,

and others will undoubtedly follow.

Most operating ASR sites are storing treated drinking water.

When recovered from storage, this water usually requires only

disinfection before being sent out to the water distribution system. In

recent years other applications of ASR technology have also begun.

In the Tampa Bay area of Florida, which is an area with tremendous growth in water demand and limited

a vailable

supplies, treated wastewater is reclaimed and piped to golf courses,

parks, gardens and other areas requiring irrigation to reduce the demand

for potable water. When the rains begin and irrigation demand ceases,

reclaimed water is stored in ASR wells in deep brackish aquifers, from

which it is recovered when needed to meet irrigation demands during dry

periods. Reclaimed water ASR is therefore beginning to be a booming

application of the ASR technology.

vailable

supplies, treated wastewater is reclaimed and piped to golf courses,

parks, gardens and other areas requiring irrigation to reduce the demand

for potable water. When the rains begin and irrigation demand ceases,

reclaimed water is stored in ASR wells in deep brackish aquifers, from

which it is recovered when needed to meet irrigation demands during dry

periods. Reclaimed water ASR is therefore beginning to be a booming

application of the ASR technology.

a

Several sites are storing untreated groundwater pumped from overlying or underlying aquifers,

or from wellfieldslocated at great distances from the ASR site. When

needed, this water is recovered from the storage zone and combined with

whatever flows are then available from the primary water sources, to

help meet peak or emergency water demands. In coastal areas subject to

salt water intrusion, or other areas subject to contamination or

overpumping, ASR is being used to achieve the full water supply benefits

of local aquifers, which are then used for water storage more than for

water production. Groundwater ASR is increasingly viewed as a desirable

application of ASR technology.

The newest ASR application is for storage of partially-treated surface water.

Prior to recharge, water is treated sufficiently to ensure that the

aquifer does not plug with particulates or organic material, and to

ensure that the aquifer is not contaminated. Generally it is anticipated

that the level of treatment will be less than that required for

production of drinking water. Stored water is recovered to help meet

peak demands for supplemental untreated water, whether for urban needs,

ecosystem protection, low streamflow maintenance, agricultural

irrigation, industrial water requirements, power plant cooling make-up

water, or other needs.

ASR is a unique technology,

different than for production wells or injection wells.

Understanding

ASR technology ensures success in almost all situations, whereas failure

to understand the unique aspects of this technology can lead to

failure, lost investment and disappointment. For anyone who may be

interested, I coined the term "aquifer storage recovery" in 1983 when

the first ASR system at Manatee county, Florida, began successful

operation. Development of this system had been underway since 1978.

Manatee county is about to start construction of their third phase of

ASR expansion to include four wells with a combined nominal capacity of

38 Ml/D (10 MGD).

No comments:

Post a Comment